Introduction:

Solar energy has gained tremendous popularity as a sustainable and renewable source of power. The seamless integration of solar photovoltaic (PV) systems into various infrastructures is made possible by essential components such as rail splices. In this blog post, we will explore the significance of rail splices in solar PV systems and their role in providing structural integrity and efficient energy generation.

1. Understanding Rail Splices:

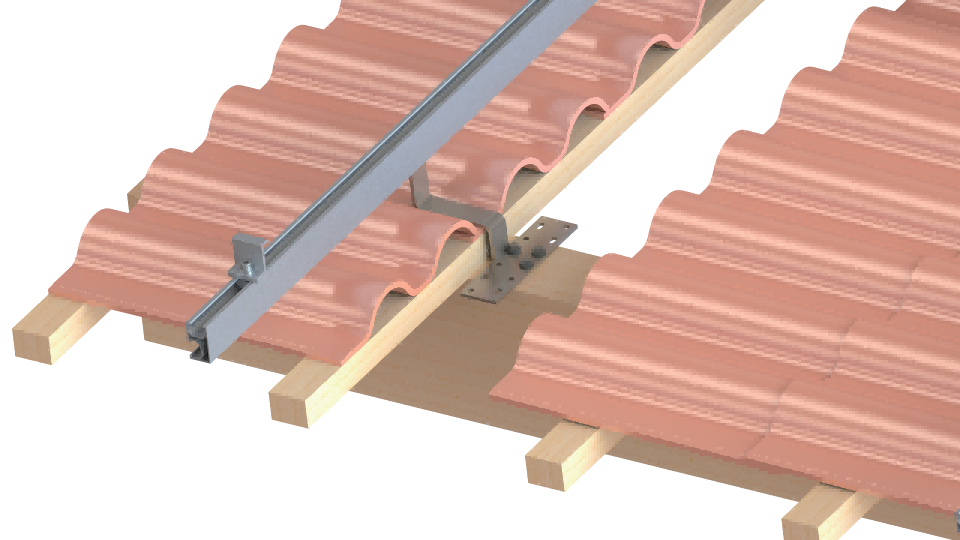

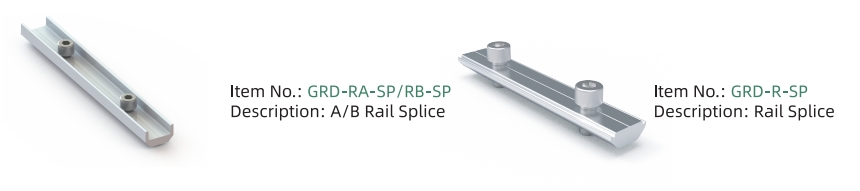

Rail splices, also known as rail connectors or rail joints, are crucial elements used to connect and secure solar panel mounting rails in a PV system. These splices are typically made of high-quality, corrosion-resistant materials such as aluminum or stainless steel. They are designed to join the rail sections seamlessly, maintaining the structural stability of the system while ensuring uniform load transfer across the mounting structure.

2. Importance of Rail Splices:

2.1 Enhanced Structural Integrity:

Rail splices play a critical role in maintaining the overall structural integrity of a solar PV system. They provide a secure connection between rail sections, preventing any movement or loosening that could compromise the stability of the system. Properly installed rail splices ensure that the mounting structure can withstand external forces, such as wind or snow loads, without jeopardizing the safety of the solar panels or the surrounding area.

2.2 Efficient Load Distribution:

By connecting rail sections, rail splices facilitate the uniform transfer of mechanical loads across the mounting structure. This load distribution is essential in balancing the weight of solar panels and optimizing the system's performance. By evenly distributing loads, rail splices help minimize stress concentration points, reducing the risk of structural fatigue and enhancing the system's longevity.

2.3 Simplified Installation and Maintenance:

Rail splices are designed to streamline the installation process of PV systems. They allow for easy and precise alignment of rail sections, ensuring a seamless and secure connection. Additionally, rail splices simplify maintenance tasks as they enable the easy removal and replacement of individual solar panels when necessary. This flexibility facilitates efficient inspection, repair, or expansion of the solar PV system.

3. Installation and Best Practices:

During the installation of rail splices, it is vital to follow the manufacturer's guidelines and engineering recommendations to ensure a proper fit and secure connection. Best practices include using appropriate fasteners, torque values, and employing anti-seize compounds to prevent galvanic corrosion. Regular inspections should be carried out to check for any signs of wear, damage, or loosening of rail splices. Prompt repairs or replacements should be conducted to maintain the integrity of the system.

4. Conclusion:

Rail splices may appear inconspicuous in a solar PV system, but their importance cannot be overstated. These connectors play a vital role in providing structural integrity and efficient load distribution, contributing to the reliable and long-lasting performance of solar installations. By ensuring the proper installation and maintenance of rail splices, solar system owners can optimize energy generation, enhance safety, and protect their investment in renewable energy.

...