In today's competitive market, brand value is increasingly important. The emergence of counterfeit and substandard products is a serious threat to brand reputation and market order. As a large lead-acid battery factory, Kaiying Power has recently discovered counterfeit batteries bearing our brand in the market. Although this is distressing, it also presents an opportunity for us to reaffirm our commitment to quality and strengthen our brand image to the market and consumers. Here are some strategies and actions we are taking in response to this incident.

1. Identifying Counterfeit Products

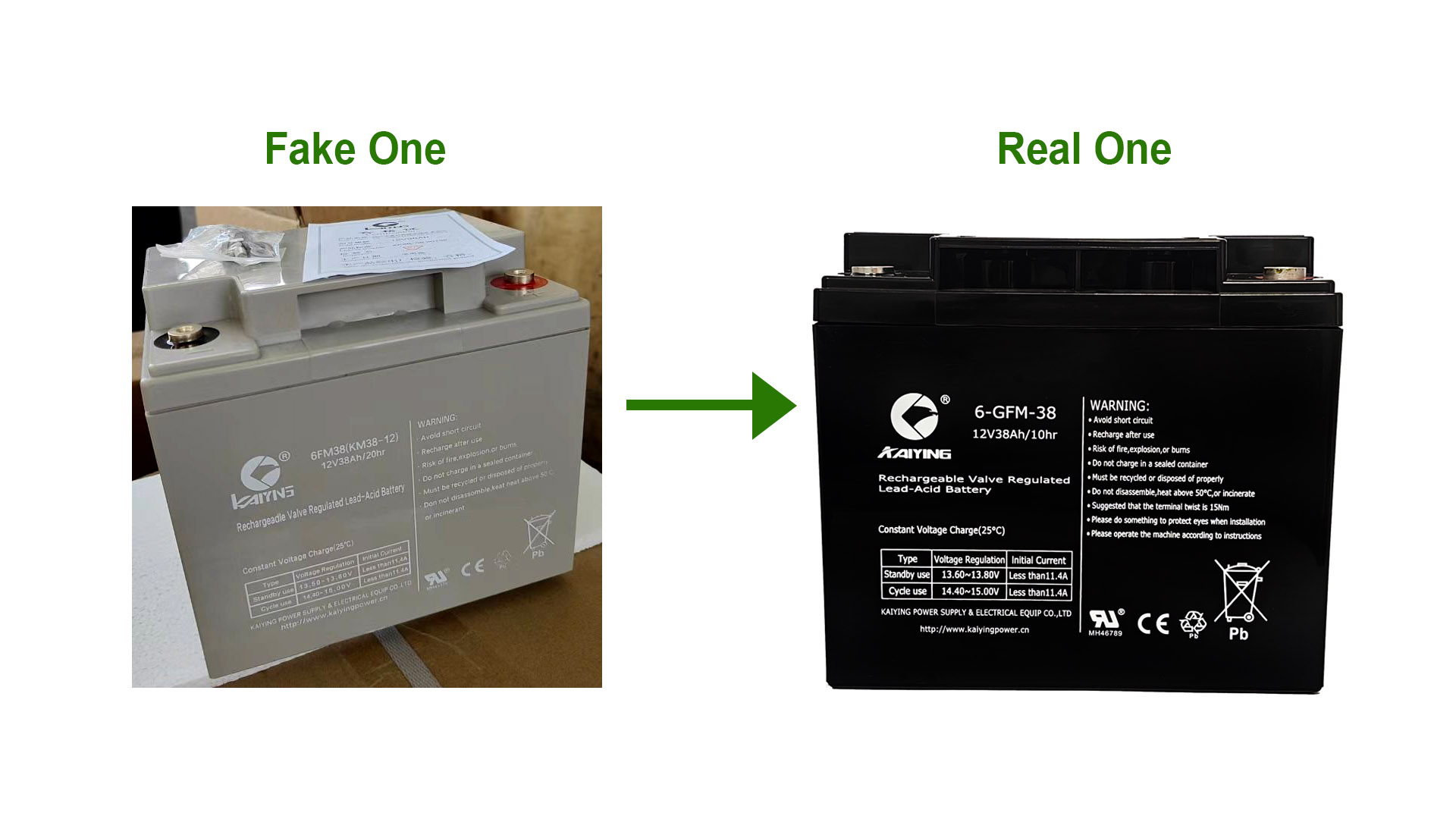

During market research, we identified counterfeit products through various issues on the battery casing, including:

Poor Casing Quality: Counterfeit batteries have thin casings with numerous scratches.

Poor Casing Quality: Counterfeit batteries have thin casings with numerous scratches.

Inferior Silk-Screen Printing: The silk-screen printing on counterfeit batteries contains errors in text, data, and certification codes, and is often blurry. These issues not only affect the product's appearance but also indicate unstable internal quality.

Inferior Silk-Screen Printing: The silk-screen printing on counterfeit batteries contains errors in text, data, and certification codes, and is often blurry. These issues not only affect the product's appearance but also indicate unstable internal quality.

Irregular Date Coding: The date coding on counterfeit batteries is irregular and does not accurately reflect the production date.

Irregular Date Coding: The date coding on counterfeit batteries is irregular and does not accurately reflect the production date.

Irregular Terminals and Acid Leakage: The terminals on counterfeit batteries are poorly made and prone to acid leakage and corrosion, which can lead to unstable connections, affecting the battery's performance and safety.

Irregular Terminals and Acid Leakage: The terminals on counterfeit batteries are poorly made and prone to acid leakage and corrosion, which can lead to unstable connections, affecting the battery's performance and safety.

These subtle differences, though easily overlooked, are crucial in quality control. Our batteries feature clear and accurate silk-screen printing, consistent laser date coding, and well-made terminals with strict prevention of acid leakage. This discovery further strengthens our commitment to quality and reminds us to focus more on detail presentation and education in market promotion. Below are some examples:

2. Comprehensive Harms of Substandard Lead-Acid Batteries to Equipment

The impact of substandard lead-acid batteries on equipment is multifaceted, mainly reflected in the following aspects:

Performance and Lifespan

Difficulty in Starting and Unstable Operation: Due to poor quality electrode materials and electrolyte, substandard batteries have increased internal resistance and rapidly decreasing discharge voltage. This not only makes it difficult to start equipment, such as motorcycles failing to start, but also causes voltage fluctuations during operation, leading to unstable equipment performance, like frequent restarts of data center servers.

Difficulty in Starting and Unstable Operation: Due to poor quality electrode materials and electrolyte, substandard batteries have increased internal resistance and rapidly decreasing discharge voltage. This not only makes it difficult to start equipment, such as motorcycles failing to start, but also causes voltage fluctuations during operation, leading to unstable equipment performance, like frequent restarts of data center servers.

Shortened Lifespan: Poor material quality can lead to incomplete chemical reactions and electrode material shedding, causing the battery capacity to drop quickly and shortening its lifespan. This increases the maintenance cost and downtime of equipment, such as the need for frequent battery replacements in UPS systems.

Shortened Lifespan: Poor material quality can lead to incomplete chemical reactions and electrode material shedding, causing the battery capacity to drop quickly and shortening its lifespan. This increases the maintenance cost and downtime of equipment, such as the need for frequent battery replacements in UPS systems.

Safety and Environment

Equipment Damage and Safety Risks: Leakage and expansion issues can cause electrolyte to corrode the metal parts and electronic components of equipment, causing damage. Moreover, the poor quality casing of substandard batteries can easily break, potentially causing short circuits, overheating, and even fires, endangering personnel and property safety.

Equipment Damage and Safety Risks: Leakage and expansion issues can cause electrolyte to corrode the metal parts and electronic components of equipment, causing damage. Moreover, the poor quality casing of substandard batteries can easily break, potentially causing short circuits, overheating, and even fires, endangering personnel and property safety.

Environmental Pollution: Substandard batteries are prone to leaking harmful substances, such as lead and acid, during use and disposal, posing a threat to the ecological environment and human health. Discarded substandard batteries can contaminate soil and water sources if not disposed of properly.

Environmental Pollution: Substandard batteries are prone to leaking harmful substances, such as lead and acid, during use and disposal, posing a threat to the ecological environment and human health. Discarded substandard batteries can contaminate soil and water sources if not disposed of properly.

Economy

Increased Maintenance Costs: Due to unstable performance, frequent inspections and maintenance are required, and the replacement frequency is high, which significantly increases the maintenance cost of equipment, affecting its economic efficiency and usability.

Increased Maintenance Costs: Due to unstable performance, frequent inspections and maintenance are required, and the replacement frequency is high, which significantly increases the maintenance cost of equipment, affecting its economic efficiency and usability.

Faced with counterfeit and substandard lead-acid batteries in the market, we understand the importance of protecting consumer rights and maintaining market order. Through strict quality control, we ensure that every battery meets high-quality standards. We not only strictly monitor the production process but also focus on detail presentation and education in market promotion to help consumers identify genuine products. Our efforts can effectively combat counterfeit and substandard products, enhance consumers' trust in the Kaiying brand, and ensure the stable operation and safe use of equipment. We will continue to uphold our commitment to quality and provide consumers with higher quality products and services.

...

Strict Quality Control: Fully automated production lines ensure consistency in every battery.

Strict Quality Control: Fully automated production lines ensure consistency in every battery. Quick Response: Support for model customization and bulk delivery.

Quick Response: Support for model customization and bulk delivery.